Twisted Choppers Mid Springer Front End Forks – USA Made Custom Fit

Don’t Compromise on Safety. Stop settling for mass-produced, imported mild steel front ends that compromise your ride quality and safety. The Twisted Choppers Mid Springer is 100% built in South Dakota for the builder who demands the best. We combine precision CNC machining with high-strength alloys to create custom forks that handle better, last longer, and keep you safe.

The Twisted Standard: 100% Manufactured in South Dakota. In a market flooded with “modified” imports, it is vital to know exactly what you are paying for. Some brands claim “USA Made” while simply taking a cheap, mass-produced import springer, swapping out the front legs, and calling it their own. We believe you deserve better.

Precision CNC Machining – No Cast Import Cores

We do not use “donor” springers. With the exception of the springs and mounting hardware, we manufacture every single component of this front end in-house.

- The “Cast” Test: Look closely at other brands. If you see rough textures, soft rounded edges, or visible mold seams on the trees or rockers, you are likely looking at a cast steel import core.

- The Twisted Difference: We CNC machine the Triple Trees, Rockers, Axles, Spring Rods, and Neck Pins directly from solid 1018 Cold Rolled Steel blocks. This ensures crisp edges, zero porosity, and exact bearing tolerances that cast parts cannot match.

4130 Chromoly Legs & Through-Tree Design

The weak point on many springer forks is where the rear leg meets the lower triple tree. Often, these are simply “butt-welded,” relying entirely on the weld for strength. We eliminate this risk.

- One-Piece Strength: Our rear legs are crafted from one continuous piece of 1-3/8″ OD 4130 Chromoly tubing that slides through the lower triple tree before being welded. This creates a mechanical lock with maximum shear strength.

- Superior Material: We use 4130 aircraft-grade alloy for both the front (3/4″) and rear legs because it is lighter and stronger than standard mild steel, providing natural vibration dampening and superior fatigue resistance.

Ride Quality & Design Features

Unlike budget springers that force you to solid-mount your handlebars, our design focuses on rider comfort and clean lines.

- The “Mid” Stance: Designed for a “Mid” width (9-3/4″ Outside), this front end offers a tighter, more agile profile than a wide glide while remaining beefier than a narrow springer.

- Vibration Dampening: The top tree uses pinch bolts and is machined to accept OEM #56161-83A riser bushings (Not included). This isolates your hands from engine and road vibration.

- Clean Setup: The bottom tree is machined to accept an internal fork stop plate, allowing for a hidden turning radius stop on compatible frames.

- Traditional Styling: Features straight front legs for a clean, classic chopper profile.

Important Fitment Notes

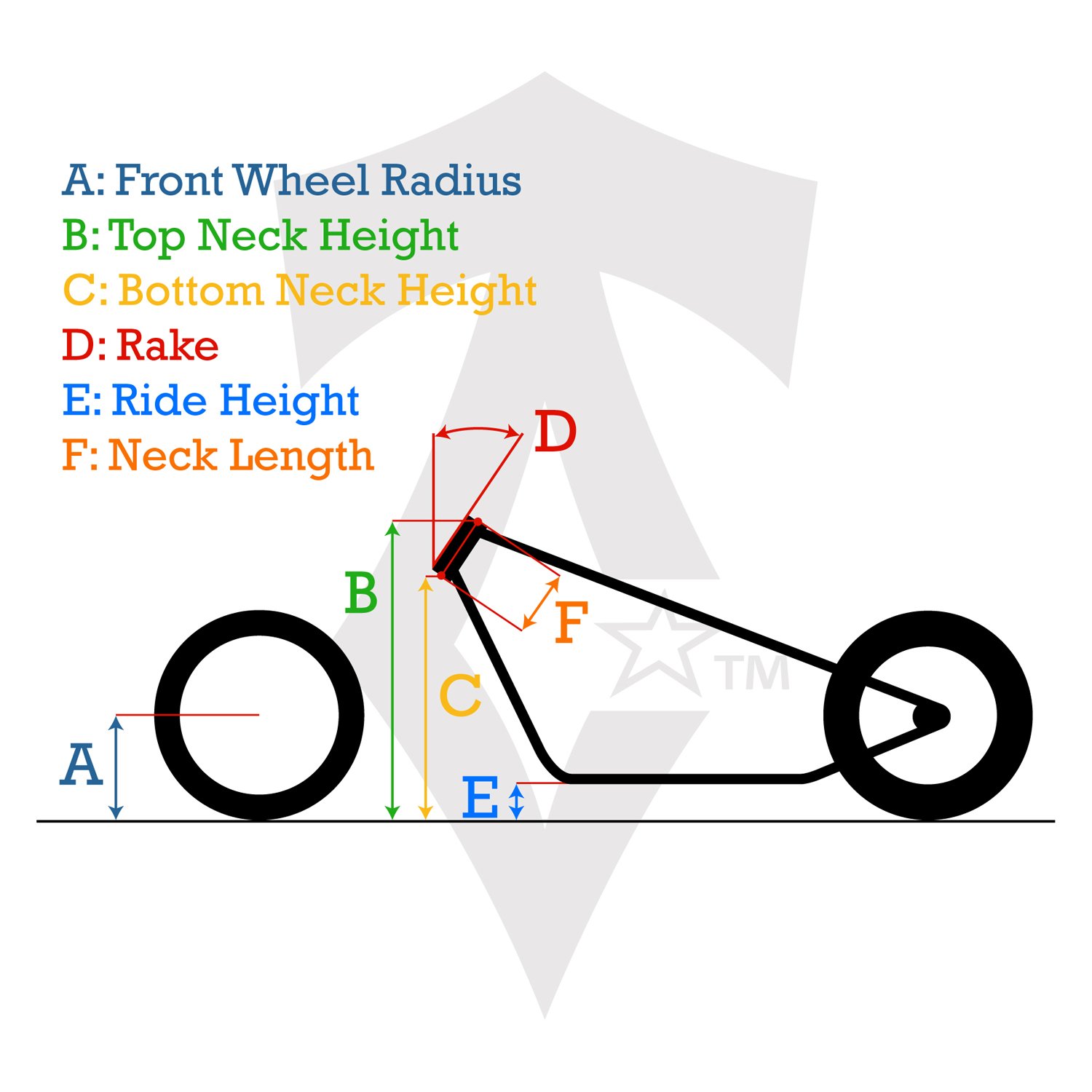

This is a custom application part designed for frames with a 1″ neck stem and standard Harley neck dimensions (Approx 7″ length). It includes a 3/4″ axle. Hub Note: Designed for Narrow Glide Hubs (Max width 4.7″). Exclusions: This model will NOT fit 2004-2022 Rubber Mount Sportsters, 1991-2017 Dyna models, or Touring models (Road King/FLT). Please see the Fitment Tab for verified model compatibility.

Reviews

There are no reviews yet